- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

BAOFENG BF-4026L Double Column Machining Center

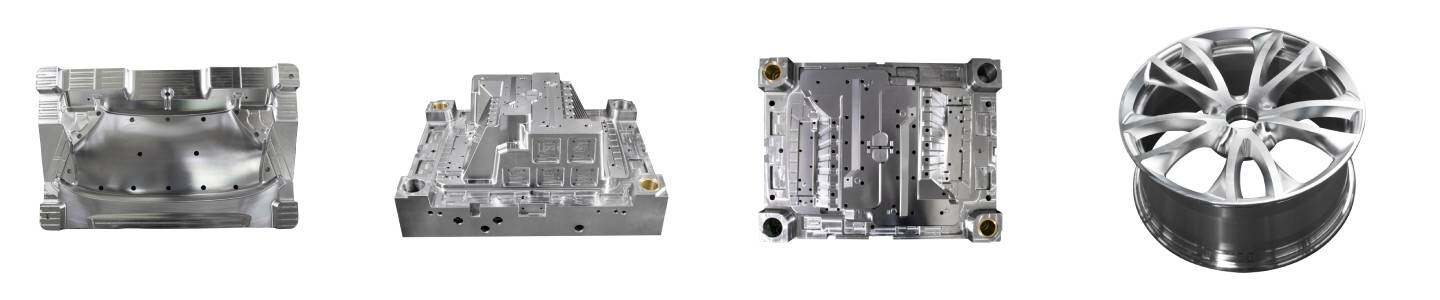

Double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts, and plate parts. It can be used for the numerical control of parts to produce large-sized products with high processing accuracy, large dimensional stability and uniform roughness.

Description:

Double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts,

and plate parts.

Special model

- Equipped with Germany ZF Gearbox or Taiwan gear type spindle box to realize strong cutting.

- Equipped with Taiwan right angle milling head to realize simple horizontal machining requirements.

- Equipped with Taiwan universal milling head to realize multiple angle machining requirements.

- Equipped with automatic pentahedron milling head to realize multiple dimension high precision machining.

Specification

| Travel | X-axis | mm | 4200 |

|---|---|---|---|

| Y-axis | mm | 2600 | |

| Z-axis | mm | 1000 | |

| Spindle nose to table | mm | 280-1280 | |

| Width of gantry | mm | 2650 | |

| Worktable | Table size | mm | 4000 x2200 |

| Maximum load on table | kg | 22000 | |

| T-slot | 11-26x200 | ||

| Controller | FANUC System | 0I-MF | |

| Spindle | Driving type | belt drive spindle | |

| Spindle speed | rpm | 6000 | |

| Spindle taper and specifications | BT50 | ||

| Spindle motor power | kw | 22/26KW-8000 rpm | |

| 3 axis motor | X/Y/ Z axis motor power | kw | 6.0/7.0/7.0 |

| X/Y/Z rapid feed | m/min | 12/12/12 | |

| Machine accuracy(X/Y/Z) | Positioning accuracy | mm | 0.005/300 |

| Repeat positioning accuracy | mm | 0.003/300 | |

| Machine | Dimension | mm | 11000x5300x5000 |

| Weight | Kg | 42000 |

Optional configuration:

- SIEMENS/FANUC/Mitsubishi CNC Controller

- 24T/30T Arm type tool magazine

- Coolant through spindle

- 4th/5th-axis rotary table

- Chip conveyor

- Tool setter

- Oil mist collector

We main sell these CNC machine as follow:

1. CNC Lathe Machine

2. VMC

3. HMC

4. CNC Turning and Milling Machine

5. CNC Drilling Machine

6. CNC Double- Column Machining Center

7. CNC 4/5 Axis

8. CNC Grinder Machine

FAQ

Q1. What's the MOQ?

A: 1 set.

Q2. What's your lead time?

A: It depends on the customer's requirement and quantity.

Q3. What's the payment term?

A: T/T or L/C. Negoiated.

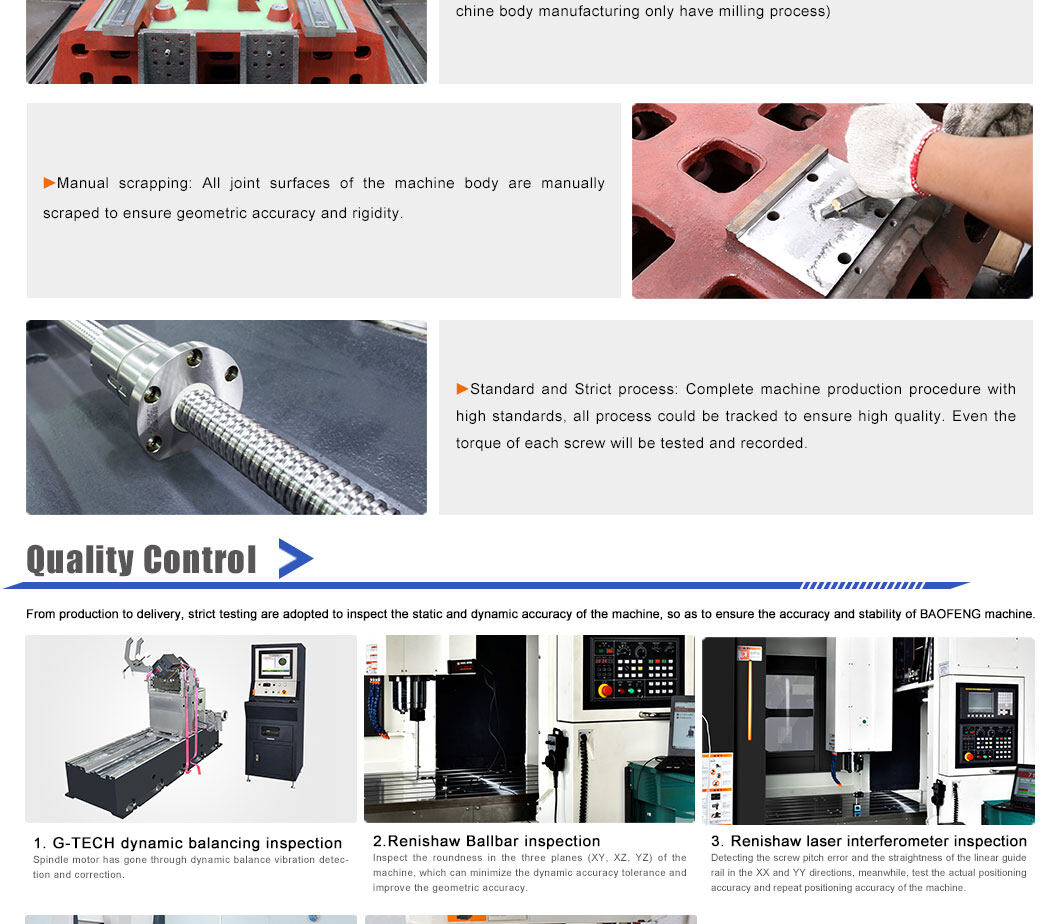

Q4. How do you guarantee the quality of your products?

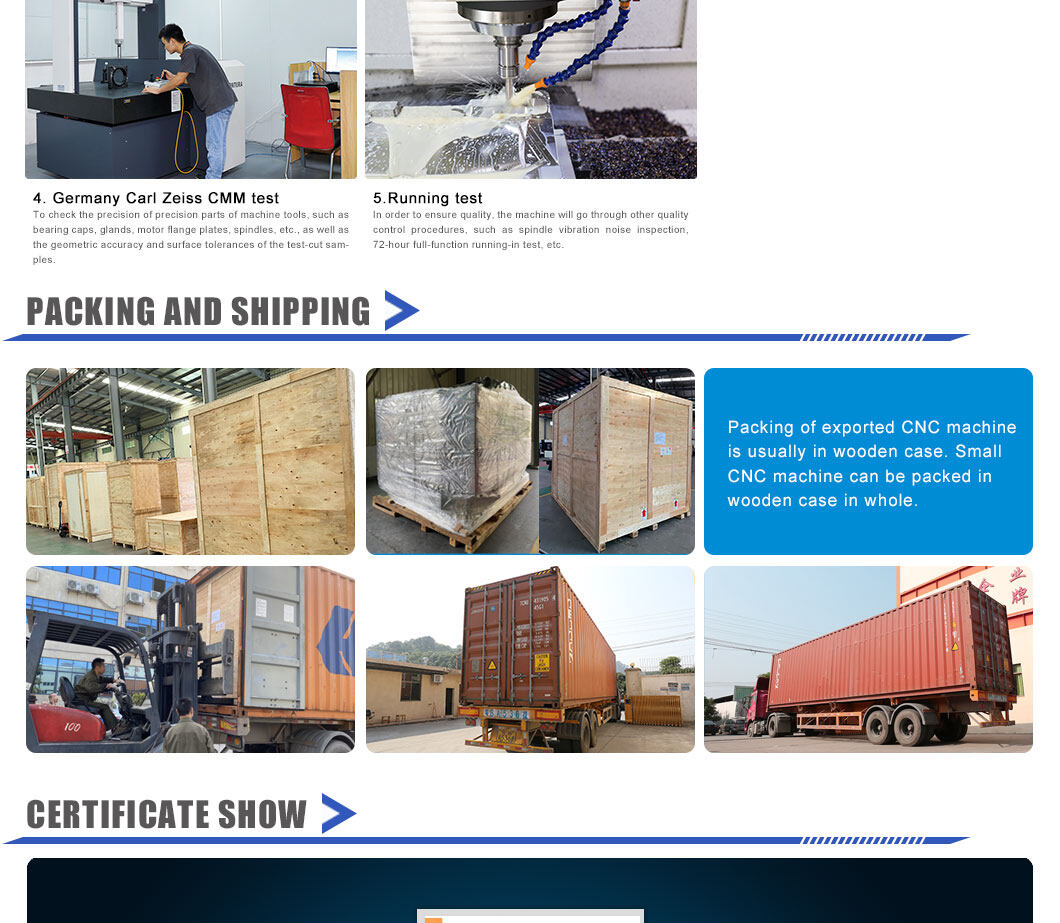

A: Each machine tests with professional Germany Inspection equipment before shipping.

Q5. Where is your factory located?

A: We have three factories in China. The biggest one is located in Huangshi City, Hubei Province;

the other two are located in Dongguan City, Guangdong Province.